BOC Group

Robert Woitsch

Type: Service

TRL: 6

BOC uses the OMiLAB Innovation Corner in combination with its digital modelling approaches (such as ADONIS, ADOIT, ADOGRC) and its physical modelling approaches (such as the Scenario Scanner) to support SMEs during their digital transformation.

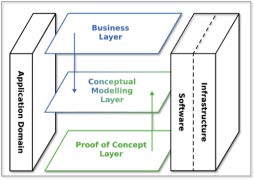

There are three abstraction layers of the industrial OMiLAB Innovation Corner at BOC.

We use the OMiLAB innovation corner – introduced above - in order to interlink the (a) business layer that is concerned with creating new business models, (b) the proof-of-concept layer that is concerned with engineering prototypes and (c) the conceptual modelling layer that is concerned with creating organisational models. The OMiLAB Innovation Corner [1] is based on the following principles:

Business Layer: Focus on Business Model Creation: A business model describes the “rational of how an organisation creates, delivers, and captures value” [2]. The aim is to either improve existing or to generate new business models. This layer therefore provides a high-level overview of the domain, the application scenario as well as the overall eco-system of the organisation. It follows the “Outcome based approach” principle, where digital innovation is always justified by the outcome.

Conceptual Model Layer: Focus on Organisational Model: Conceptual models are successfully applied in enterprise modelling [3] and information systems [6] and hence capable to describe how the digital solution is applied within an organisation. The digital innovation is therefore described in a technology independent way using a knowledge-based approach. The knowledge can be interpreted by computer algorithms or by human experts, depending on its model-representation. Hence, we follow the principle to “Invest on use cases and not technology” as the organisational models can be realised with different technologies.

Proof-of-Concept Layer: Focus on Robot Interaction: Rapid prototyping [4] is “… the idea of quickly assembling a physical part, piece or model of a product“. We apply rapid prototyping for both the development of a software application as well as for the development of a physical device. The engineering of rapid prototypes is performed by configuring and integrating pre-packaged features that are provided as services. Instead of fully implementing the prototypes, we apply the “Fail Fast, fail cheap” principle by rapidly composing features in form of services that emulate the main behaviour of the intended solution.

The aforementioned layers can be mapped to the three phases of design thinking, “Ideate”, “Prototype”, and “Test” [5], we explicitly consider that projects may focus only on one or two phases, that phases are visited in no particular order as well as that the phases are worked out in a sequence.

The ideation is supported with a creative environment, enabling co-creation of digital twinning scenarios. Tools like Scene2Model are provided for model-driven workshops.

The prototyping and making is supported with demonstration robots and a sensor farm, enabling to rapidly create “haptic prototypes” as a communication media.

The test and experimentation is supported with a full-fletched modelling environment that enables the simulation, analysis and assessment of different digital twin scenarios.

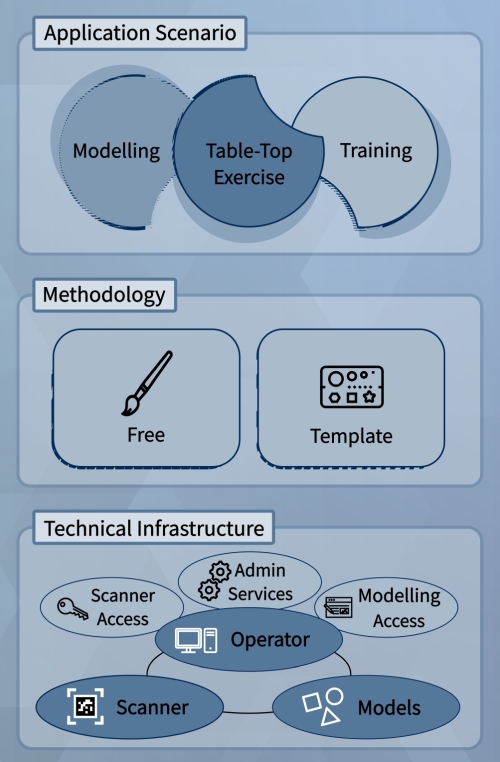

A corresponding hybrid modelling environment is the Scenario Scanner: Digital twinning application scenarios can be modelled via digital, physical and hybrid modelling approaches. Experimentation in form of table-top experiments simulate digitalization and digital twinning scenarios to play through procedures, reveal alternatives and approve corresponding models such as underlying production processes. Trainings ease the usage of different technologies and related process changes. Aligned with the application scenario, the methodology can either be an open generic approach for ideation or provide more structuredness using pre-configured templates for targeted experiments and trainings. The technical infrastructure for hybrid modelling consists of (a) modelling infrastructure in form of haptic figures, classes as well as underlying meta models serving as a foundation for digital modelling, (b) the Scanner including cameras, a tripod and edge devices serving as a foundation for physical modelling and digitalizing physical models, and (c) the operator connecting physical and digital infrastructure services including corresponding administration services.

The modelling environment can be used to access the marketplace, hence items from the marketplace in form of ideas, success-stories, solutions, technologies or experts are provided during the workshop.

List of References.

-

Woitsch R., Industrial Digital Environments in Action: The OMiLAB Innovation Corner, in Grabis J., Bork D. (Eds), The Practice of Enterprise Modelling, 13th IFIP Working Conference PoEM 2020, LNBIP 400, pp. 8-22, Springer 2020.

-

Osterwalder, Alexander; Pigneur, Yves; Clark, Tim (2010). Business Model Generation: A Handbook For Visionaries, Game Changers, and Challengers. Strategyzer series. Hoboken, NJ: John Wiley & Sons. ISBN 9780470876411

-

Sandkuhl, K., Fill, H. G., Hoppenbrouwers, S., Krogstie, J., Matthes, F., Opdahl, A., Schwabe, G., Uludag, Ö., & Winter, R. (2018). From expert discipline to common practice: A vision and research agenda for extending the reach of enterprise modeling. Business & Information Systems Engineering, 60(1), 69-80.

-

Techopedia, Rapid Prototyping, https://www.techopedia.com/definition/9093/rapid-prototyping, last access: 16.09.2020.

-

Malamed C., Learning Solutions, https://learningsolutionsmag.com/articles/a-designer-addresses-criticism-of-design-thinking, last access: 16.09.2020.

IPR / Licence

The OMiLAB Innovation Corner Approach is open source provided by OMiLAB NPO at https://www.omilab.org.

The ADOxx meta modelling platform for academic purpose is open use and a set of model-based solutions are open source provided by BOC at https://www.adoxx.org.

The usage of the industrial OMiLAB Innovation Corner at BOC is a consulting services.

The modelling software used in the resulting digital twin are commercial licenses.

Contact Person

Information

-

OMiLAB Brochure: https://www.omilab.org/brochure/

-

Webpage OMiLAB NPO https://www.omilab.org

-

Tutorial: Industrial Digital Environments in Action: The OMiLAB Innovation Corner

-

Slides: The Industrial OMiLAB Innovation Corner in Vienna: Modelling of Intelligent Behaviour: https://www.omilab.org/activities/events/omilabday2020/material/3_Robert_Woitsch_Digital_Innovation-OMiLAB_Innovation_Corner_PUBLIC.pdf

-

Webinar: Simulating event logs in production processes

Use

- Material Collection: https://adoxx.org/live/web/change2twin/downloads

Extend

-

Physical Experiment of a Paint Production Process: https://git.boc-group.eu/change2twin/graphenstone-virtual-lab/-/raw/master/DOC/OMiLAB%20Laboratory%20Experiment%20for%20Production%20Processes_03032021.pdf

-

Access to the Physical Experiment of a Paint Production Process: https://innovation-laboratory.org/experiments/paint-production/overview/#

-

Meta Modelling Developer Community: https://www.ADOxx.org

-

Sumereder A., and Dokken T. (2022). Model-Based Guide Toward Digitization in Digital Business Ecosystems. In: Karagiannis D., Lee M., Hinkelmann K., Utz W. (eds) Domain-Specific Conceptual Modeling. Springer, Cham. https://link.springer.com/chapter/10.1007/978-3-030-93547-4_18.

-

Woitsch R., Sumereder A., and Falcioni, D. (2022). Model-based data integration along the product & service life cycle supported by digital twinning. Computers in Industry, Volume 140, 103648. ISSN 0166-3615.

-

Sumereder A. and Woitsch R. (2022). Digitization Principles for Application Scenarios towards Digital Twins of Organizations. ECCOMAS Congress 2022 - 8th European Congress on Computational Methods in Applied Sciences and Engineering. https://www.scipedia.com/public/Sumereder_Woitsch_2022a.

-

Sumereder A., Falcioni D. and Woitsch R. (2024). How Scenario Building supports Conceptual Modelling. RCIS 2024 Workshops and Research Projects Track, May 14-17, 2024, Guimarães, Portugal. https://ceur-ws.org/Vol-3674/RP-paper7.pdf.